Confined Space Hazards – four main causes of serious accidents

In this article, we look at the most common accidents taking place in confined spaces. Based on relevant work safety literature, we present the main causes of serious accidents related to confined space entry. We also address the issue of determining which atmospheric hazards should be measured in a confined space that will soon be entered and explain how Gasmet helps you solve this challenge.

Working in a confined space

For a long time, working in a confined space has been identified as a remarkable risk factor in various industrial settings. Often defined as a space large enough for workers to enter, with limited or restricted means for entry or exit, and not designed for continuous occupancy, a confined space is connected to most of the potential risks found in places such as plants and manufacturing sites. Typically confined spaces include tanks, vessels, silos, storage bins, hoppers, vaults, pits, maintenance holes, tunnels and pipelines.

A comprehensive occupational safety study conducted in 2017 states that “among the types of accidents, those related to confined space activities have the highest ratio of fatalities to lost-time injuries (1:2)” 1. The overall fatality rate in confined space work is estimated to range between 0.05 and 0.08 per 100,000 workers 2. This is the reality even though occupational safety and security matters in confined spaces have received a great deal of attention in occupational safety literature as well as in industrial worksite practices and procedures.

What makes confined space work so overrepresented in these charts? In order to have a better understanding, we need to look at the underlying reasons leading to the accidents. Below, we have listed the four main categories which most of the confined space accidents fall into.

What are the most common hazards in confined space entry?

A recent study identified four main causes of confined space accidents that lead to injuries, namely:

- Toxic atmospheric hazards

- Flammable atmospheric hazards

- Engulfment

- Physical hazards

Let’s look at each of these in turn.

Toxic atmospheric hazards can be roughly divided into two categories:

- Asphyxiation caused by low levels of oxygen. In these types of cases, oxygen has been replaced by other gases, such as nitrogen or carbon dioxide.

- Inhalation of harmful airborne contaminants, such as toxic gases, vapors, fumes and dust.

Accidents and rescue operations related to a toxic atmosphere typically pose a great risk for the rescuers. There are numerous reported cases where rescuers entering a confined space lost consciousness, making the entire rescue operation riskier and more complex.

Flammable atmospheric hazards refer to injuries resulting from fires and explosions in a confined space. In many countries, the quantity of flammable or explosive gases is expressed as a percentage of the Lower Explosive Limit (LEL), the most common LEL being 10% or lower.

Engulfment is the result of being immersed in a liquid, such as oil or water, which then leads to drowning or asphyxiation. Engulfment can also be caused by free-flowing solids, such as rocks or dirt. It has been observed that “particular danger results when stored materials form a crust above a void and a worker or workers walking on top of the crust, or working below the crust, are engulfed when the crust gives way”.

A noteworthy portion of confined space-related fatalities stems from physical hazards. These might include “falls from height, being struck by falling objects, entrapment in machinery, and electrocution” 2. Interestingly enough, many physical hazards and injuries are connected to atmospheric ones: exposure to low oxygen levels or toxic gases might lead to a worker losing consciousness and falling from a great height or drowning in a pool of liquid.

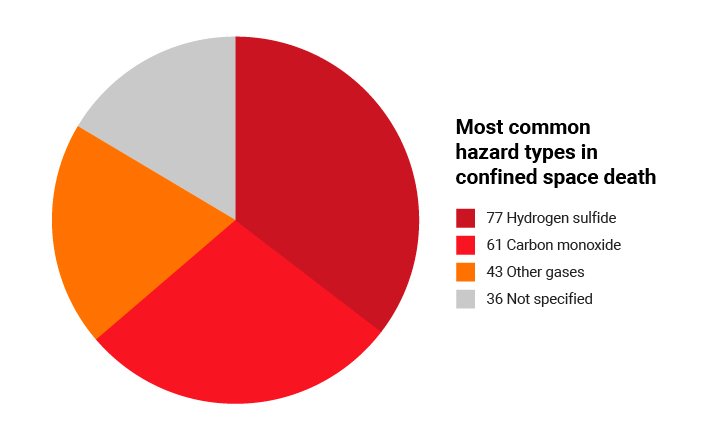

It is noteworthy that atmospheric hazards are the cause of 62% of all accidents taking place in a confined space 2. The high percentage tells us that the invisible atmospheric dangers are certainly a characteristic of confined spaces but, also, that there remains work to do in how we identify and counteract these risks.

Safe processes, proper equipment

While the literature on and practices of accident prevention in confined spaces have come a long way, there is room for improvement as long as fatal accidents exist.

As in all risk-preventing activities, the starting point will always be having a company/work culture that allocates sufficient time and resources for risk assessment while encouraging everyone to take safety matters seriously. A strong culture of risk prevention lays the foundation for creating comprehensive and functional confined space entry processes and procedures.

Our role at Gasmet is to provide ambitious occupational safety professionals and their processes with the kind of confined space entry equipment they need to successfully complete their work.

Our contribution to the field has been to take the guessing and uncertainty out of the equation by offering confined space workers the possibility to detect and monitor not just a few, but essentially all of the imaginable hazardous compounds in a confined space — simultaneously with just one gas analyzer. Identifying a wide variety of toxic and flammable gases, such as carbon monoxide, acetone, chloroform, acetylene, butane and methane, makes decisions regarding confined space entry fact-based and straightforward.

By raising the bar in the way we monitor atmospheric hazards in confined spaces, we wish to empower ambitious safety professionals to make safer confined space entries a reality for tens of thousands of workers throughout the world. Our slogan at Gasmet is Know What’s in the Air. And knowledge is key in confined space work.

References

1 P. Hämäläinen, J. Takala, T.B. Kiat. Global estimates of occupational accidents and work-related illnesses, World Congress on Safety and Health at Work, Singapore (2017), pp. 3-4

2 J. Selman, J. Spickett, J. Jansz, B. Mullins. An investigation into the rate and mechanism of incident of work-related confined space fatalities. Saf Sci, 109 (2018), pp. 333-343

3 Safe Work Australia, Code of Practice: Confined Spaces, Commonwealth of Australia, Canberra, ACT (2016)

4 A.J. Suruda, T.A. Pettit, G.P. Noonan, R.M. Ronk. Deadly rescue: the confined space hazard, J Hazardous Mater, 36 (1) (1994), pp. 45-53

5 We Must Change the Statistics of Confined Space Injuries and Fatalities, 2018, https://ohsonline.com/Articles/2018/08/01/We-Must-Change-the-Statistics-of-Confined-Space-Injuries-and-Fatalities.aspx?Page=2

| Confined Space Air Monitoring

Before entering a space that might contain hazardous gases, you must complete a pre-entry check with confined space equipment. This is usually done by lowering a gas detector to space or by inserting a probe or tube and pumping air into the gas analyzer. These areas should be monitored every time before entering and whenever workers are present. Learn more about solutions for Confined Space Air Monitoring |

|